Form synthesis

Published on

In a world where technology is rapidly evolving and innovation is a constant occurrence, improving the process of creating engineering components and systems becomes an integral part of progress. This process involves seeking inspiration from a wide variety of sources, from nature to artificial intelligence, with the aim of rethinking traditional design approaches. New paradigms in design open up possibilities for creating products that not only perform their functions more efficiently but are also better adapted to changing conditions and requirements.

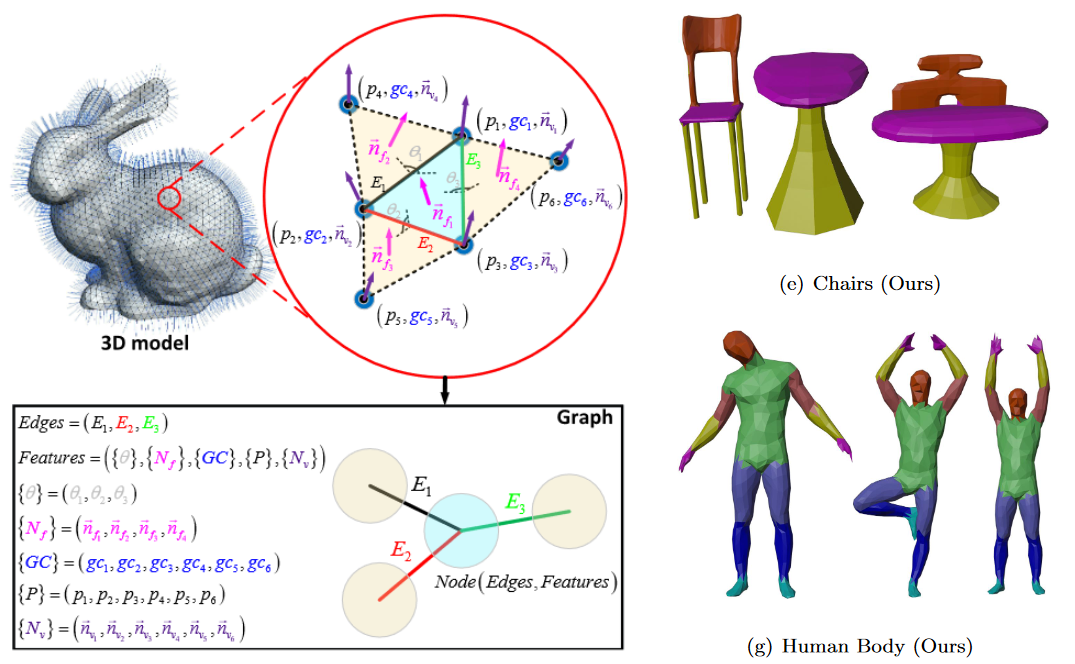

Utilizing the principles of model training based on existing samples, important attributes of their geometry are first highlighted - such as the position of faces, the angle of inclination relative to adjacent surfaces, local surface curvature, and so forth. This method of classifying and differentiating three-dimensional objects and their component parts opens up new prospects in the field of design.

The model trained in this way can become a tool for generating new objects or combinations thereof. However, the results may appear as familiar objects, but they can also be devoid of the meaning that we imbue into them. An illustration of this can be the distorted human anatomy generated in images - eerily recognizable but with oddities, for example, seven fingers. Similarly, when generating three-dimensional objects, we might produce something that closely resembles the shape of scissors, but with functional shortcomings that don’t even allow the blades to fully close.

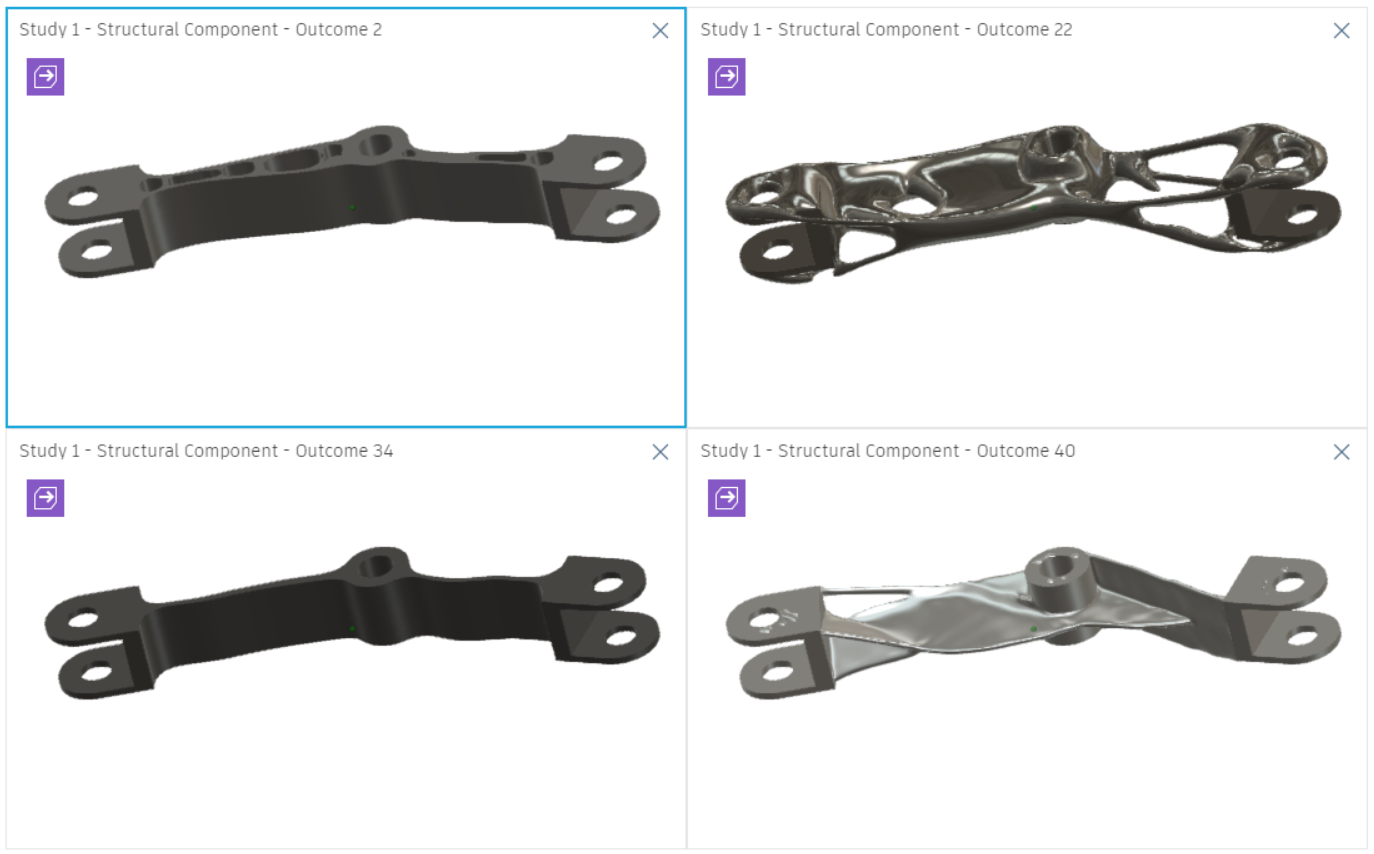

There is a saying that an ugly airplane won’t fly, but the shapes of parts in design are primarily dictated by their functionality. Of course, a lot also depends on the method of production - in most cases, a simple stamped bracket will do, rather than an expensive part obtained through topological optimization and printed on a 3D printer. However, the advancement of manufacturing methods simplifies the creation of complex-shaped parts, and all possible variants should be taken into account during the design process. At present, a choice must already be made at the initial stage of design: to create a part for more traditional manufacturing methods (stamping, milling, turning, etc.) using CAD, or to resort to CAE with topological optimization to obtain a complex-shaped part, which is most often achieved using casting, 5-axis machining, or 3D printing. A rare exception is Autodesk Fusion 360 with the Generative Design add-on, which allows for optimization not only taking into account load, but also manufacturing methods and the cost of the part.

Nevertheless, this design method still does not fully operate on the functional purpose of the object, but only on part of it in the form of operating conditions, under which the part is adapted. The nodal elements (lugs and axis) from the example in the previous image were pre-designed manually and excluded from optimization. These elements are quite understandable and simple in functionality. Even now, it seems possible to train models to obtain these elements without exhibiting undesirable mutations, as in the example with the scissors. But there are still questions: how and what to train these models on? If we resort to classification by a set of known parts with the definition of only distinctive features of their geometry, we will be severely limited. Of course, creating parts from such models will be fast and simple, like generating images: “salmon swimming against the current” / “chuck jaws of a lathe”.

Images, by their nature, are maximally saturated with information - a photograph of a tree reproduces the tree itself, and on a newly generated image based on these photographs, there will be another tree that does not fall short of the original. The functional purpose of this new tree will lie in its external resemblance to the original. Obviously, it won’t be used as a basis for studying leaf anatomy (or at least it shouldn’t be). Similarly, a part obtained by this approach will more resemble the requested part in appearance, rather than fully perform its functions. Unlike trees, which have evolved over millions of years, the parts used to train models are comparatively new. Machines and systems created based on these parts often fall short of organic systems. Humanity is not willing to accept the time constraints of natural evolution, and in order to circumvent them, a deeper understanding of the essence of the objects we create is necessary.

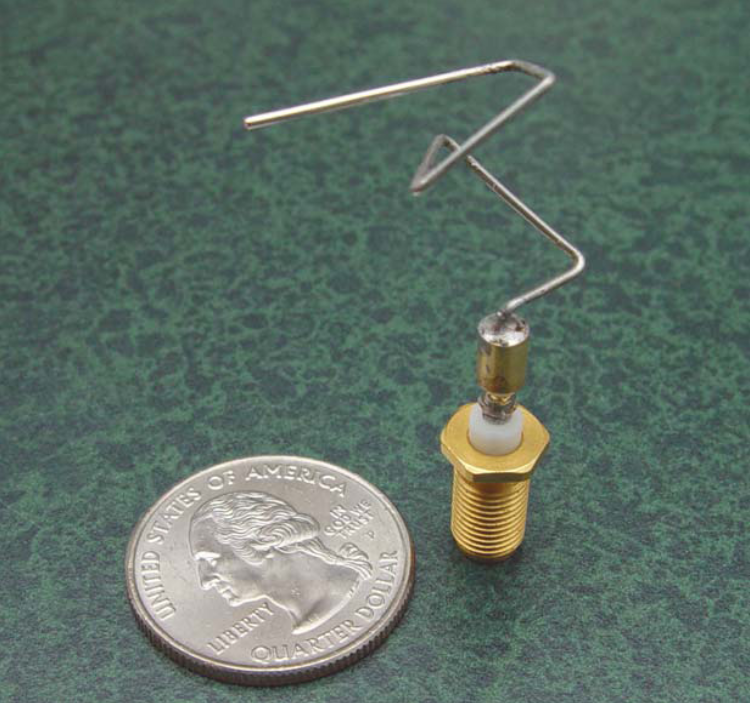

If we start by understanding how a device functions, and based on that, select its shape, we would find objects that might look unfamiliar but perform their functions much better. One of the classic examples of such outcomes is the antenna for NASA’s spacecraft developed using an evolutionary algorithm. The primary goal was to achieve a superior directional pattern in a given frequency range. The result exceeded all traditional designs, was lighter, and cheaper to manufacture. Importantly, NASA’s report highlighted a reduction in time spent from 5 to 3 person-months on antenna creation, which was a significant advantage when antenna characteristics needed to be adjusted due to changes in the spacecraft’s mission.

The intersection of machine learning, generative design, and engineering opens unique opportunities for the creation of more complex, efficient, and adaptive systems and components. This is a new path that offers a fresh perspective on product design, taking into account not just appearance but also functionality, operational conditions, and manufacturing requirements.

However, on this journey, we are faced with a set of important questions and issues that need to be addressed. How do we train models to understand functional requirements? How do we combine generative design with traditional manufacturing methods? And how do we create models that can adapt to changes in project conditions and goals? The answers to these questions could lead to new and effective solutions. In a world where technology is rapidly advancing, the ability to adapt and develop innovations will be key to a successful future. The integration of generative design and machine learning into manufacturing processes is just the beginning of this journey.

This work is licensed under a Creative Commons Attribuition-ShareAlike 4.0 International License .