A bit about engine design

Published on

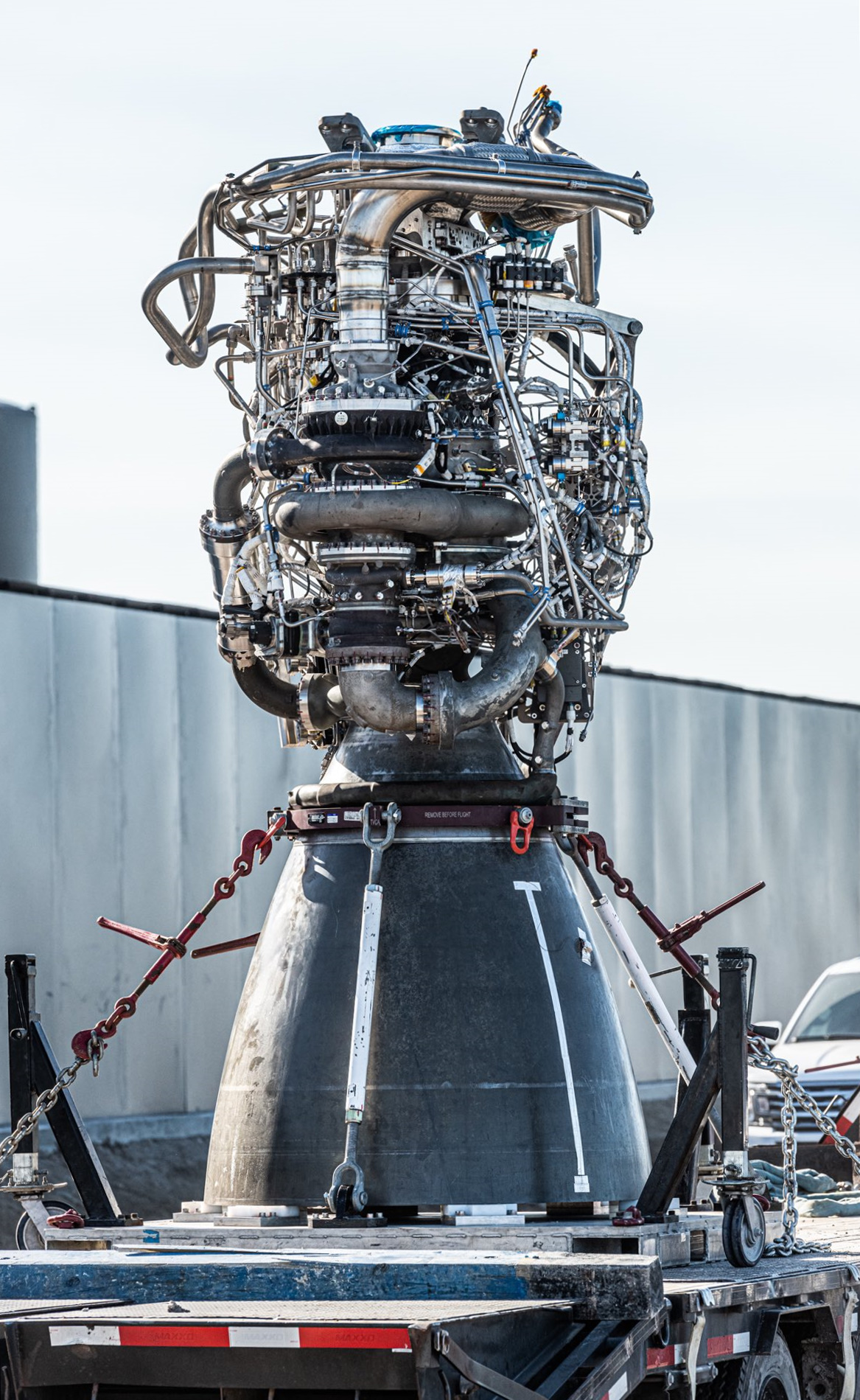

Like most liquid propellant rocket engines, the Raptor harness contains many components that control the engine’s operation. At the same time, with an increase in technical perfection, the number of strapping elements also increases. The high demand for these engines as part of the Starlink satellite deployment plan has contributed to the acceleration of their production. Part of the payment for speeding up production fell on the harness - designed initially exclusively for ground testing of early versions of the engine, it iteratively turned into a system suitable for flights with smaller dimensions and fewer connections. An undoubted advantage is the ability to try different schemes and include additional sensors in the composition. The production technology facilitated at the initial stages (many connections using flanges were later replaced with welded ones) with the absence of strict requirements for weight and dimensions simplified the development.

However, designing such complex systems is always associated with an increase in the cost of making changes as the project progresses. In my experience, I encountered such a phenomenon long before I found out about it, even while writing a diploma in rocket engine design at Bauman Moscow State Technical University. With each problem that arose, it was necessary to roll back the work a significant number of steps back and change the calculations. After several such moments, I decided to convert the entire calculation part from the initial data to obtaining the internal geometry of the engine into a single parametric program that connects my own calculation expressions and third-party programs. This approach freed up a significant amount of time for solving truly time-consuming and intellectual tasks.

Looking at the photos of the Raptor, I’m very glad that piping was not one of our goals when designing the engine. Creating only a parametric program for internal characteristics and geometry required the establishment of large decision trees. After graduation, I worked on projects that were not so much related to the design of such complex systems, but I continued to be interested in similar issues.

This work is licensed under a Creative Commons Attribuition-ShareAlike 4.0 International License .